Roto Moulded Pellets

1. Introduction: The Marvel of Roto Moulded Pellets

Roto Moulded Pellets, a cornerstone of modern plastic manufacturing, have revolutionized industries worldwide. These versatile pellets, crafted through rotational molding, find applications in various sectors, including automotive, agriculture, and packaging.

2. What are Roto Moulded Pellets?

Roto Moulded Pellets are small plastic beads, typically made from high-quality polymers. Through the meticulous process of rotational molding, these pellets are transformed into intricate shapes used in manufacturing a myriad of products.

3. The Process of Roto Moulding

3.1. Raw Material Selection and PreparationRoto Moulded Pellets begin their journey with the careful selection of raw materials. Polyethylene, polypropylene, and PVC are common choices. These materials are then processed into uniform pellets, ensuring consistency in the final product.

The molding process involves heating the pellets within a mold, allowing them to evenly coat the interior. As the mold rotates, the molten plastic adheres to the mold’s surface, creating a seamless and durable product.

4. Applications Across Industries

Roto Moulded Pellets have found their way into a myriad of industries, showcasing their versatility and durability.

4.1. Automotive IndustryIn the automotive sector, these pellets are used to create sturdy components such as fuel tanks and bumpers. Their lightweight nature enhances fuel efficiency without compromising on durability.

4.2. Agricultural SectorRoto Moulded Pellets play a vital role in agriculture, crafting irrigation systems, tanks, and containers. Their resistance to corrosion and harsh weather conditions makes them an ideal choice for agricultural applications.

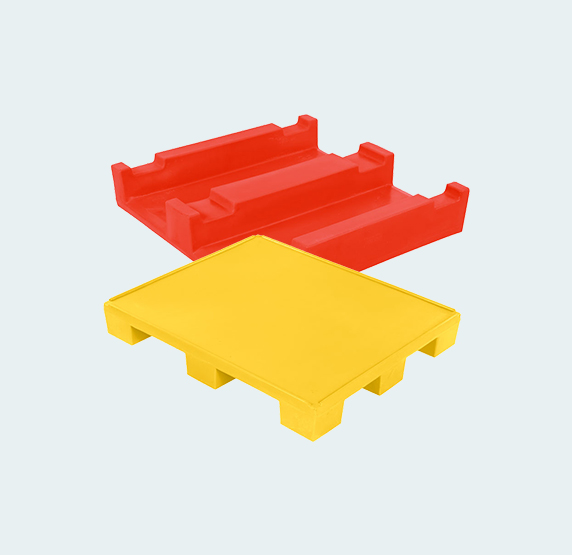

4.3. Packaging SolutionsFor packaging solutions, these pellets are utilized in crafting crates, pallets, and containers. Their robustness ensures the safe transportation of goods, reducing the risk of damage.

5. Benefits of Roto Moulded Pellets

5.1. Durability and LongevityRoto Moulded Pellets exhibit exceptional durability, ensuring products withstand wear and tear over extended periods. This longevity translates into cost-effectiveness for businesses.

5.2. CustomizationManufacturers can tailor Roto Moulded Pellets to meet specific design requirements, allowing for the creation of unique and intricate products.

5.3. Environmental FriendlinessMany Roto Moulded Pellets are recyclable, contributing to a more sustainable manufacturing process and reducing the environmental impact.